SMARTer Machine

Overview

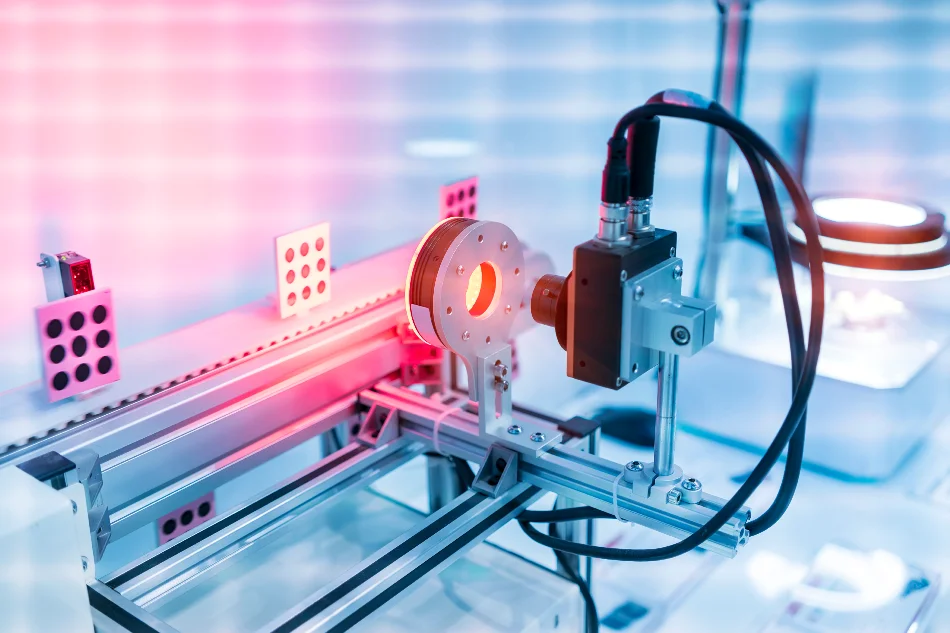

Our approach to Industry 4.0 embraces cutting-edge technologies to redefine production processes. SMARTer Machine solutions empower organizations to adapt, innovate, and accelerate production in a dynamic business environment. The dedicated team focuses on creating intelligent solutions for seamless, safe, and digitally-driven industrial interactions. By combining extensive industry experience with the latest in technology and analytics, we enhance the machine-human experience. SMARTer Machine projects span automation to precision engineering, positioning partners and clients to excel in an era of continual innovation. Our core philosophy recognizes machines as the industry's foundation, driving creative transformation in manufacturing processes.

Flexibility

Quality Control

Improved Efficiency

Safety

Customization

Gold Wire Management System (GWMS)

GWMS consists of a set of automated robots that are used to load and unload gold wire spools from storage, as well as to dispense gold wire to wire bonding machines. It can help to improve the efficiency and traceability of gold wire usage, as well as to reduce the risk of contamination.

ADDRESS

Penang Main Office

9, 1, Jln Industri Tangkas, Taman Industri Tangkas,

14000 Bukit Mertajam Penang.

Penang Beta

6 & 8, Lorong Perindustrian Bukit Minyak 1/1,

Kawasan Perindustrian Bukit Minyak,

14100 Simpang Ampat, Pulau Pinang

Kuala Lumpur

21-13A & 21-16, Stellar Suites, Jalan Puteri 4/7,

Bandar Puteri, 47100 Puchong, Selangor.

Tel: (603) 8604 7311

SOPHIC AUTOMATION SDN BHD

(2007010136965(794994-D))

A pure play technology company, we have delivered proven automation solutions and engineering services to more than 50 MNCs & SMEs in South East Asia.

Email: enquiry@sophicautomation.com

©2023 Copyright Sophic Automation Sdn Bhd. All Rights Reserved | Terms of Use | Privacy | Site Map