We Provide Smarter Machines to Transform Your Business!

Smarter machines can automate repetitive and routine tasks, freeing up employees' time to focus on more complex and creative work.

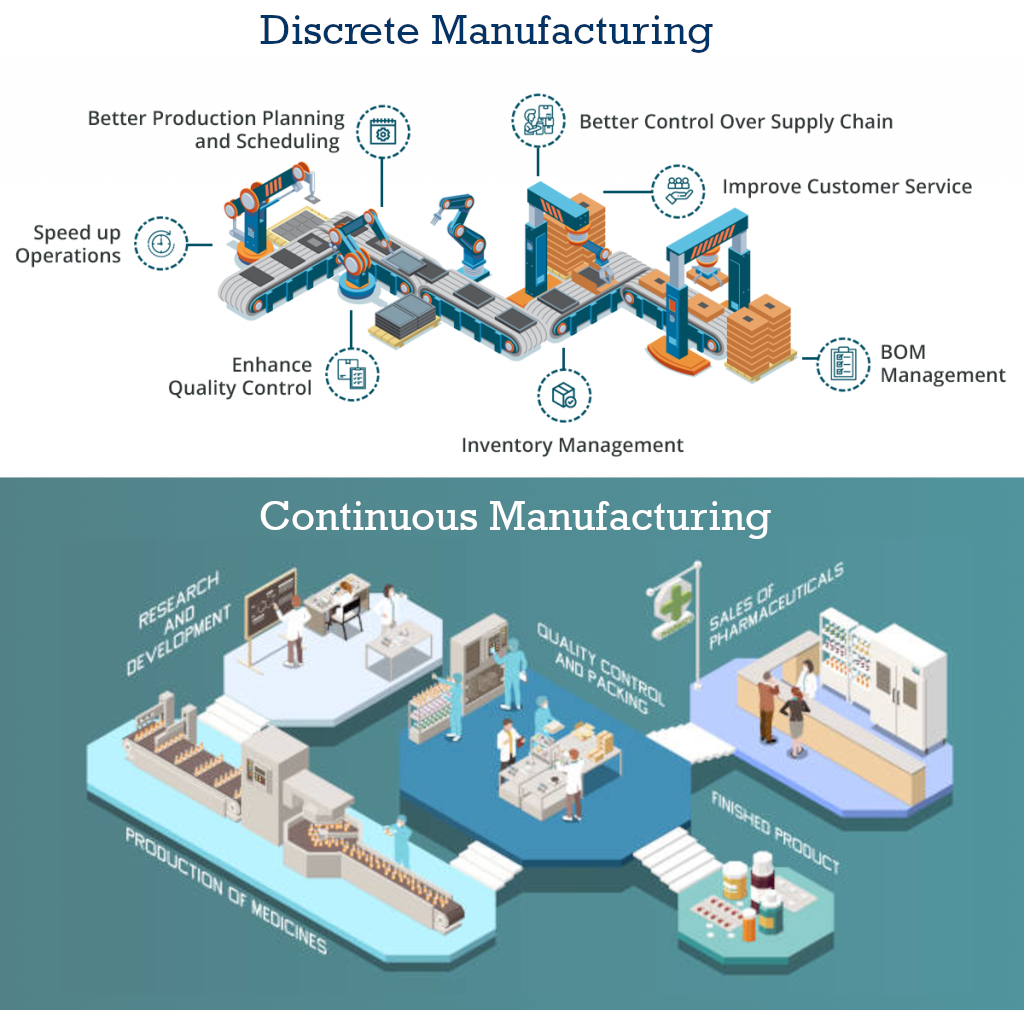

Autonomous Manufacturing: Discrete vs Continuous

Discrete manufacturing refers to the production of distinct and individual items that are separate and identifiable units. Each item is typically produced separately and has its own unique characteristics. Products that can be easily counted and distinguished, such as automobiles, electronic devices, furniture, toys, and clothing.

Continuous manufacturing refers to the production of goods in a continuous and uninterrupted manner. The production process runs continuously, with no breaks between each unit's production. Products that are homogeneous and have consistent properties throughout, such as chemicals, liquids, fuels, and steel.

Why Automation?

Here are the reasons why you need to automate with machines and robots in manufacturing.

Improved Efficiency

Perform tasks such as assembly and material handling with greater speed and accuracy.

Cost Reduction

Reducing labor costs, minimizing waste, and improving energy efficiency.

Flexibility

Perform a wide range of tasks with greater flexibility in manufacturing processes.

Quality Control

Perform quality control tasks such as inspection and testing with greater accuracy and consistency.

Data Collection and Analysis

Collect data on production processes, performance & quality for real-time monitoring and analysis.

Customization

Programmed to produce customized products with high precision and minimal waste.

Safety

Perform dangerous tasks such as handling hazardous materials or operating heavy machinery.

SMARTer Warehouse

Warehouse Management System (WMS)

Interconnected warehousing technologies and automate everything with minimal errors

WMS solutions vary in complexity and can be tailored to meet the specific needs of different industries and organizations. They are widely used across industries such as retail, e-commerce, manufacturing, distribution, and logistics to streamline warehouse operations and enhance supply chain management.

It helps organizations efficiently manage their storage, distribution, inventory, order fulfillment, and overall logistics processes. Whether for within a warehouse or distribution center or as part of the supply chain, it's a crucial tool for businesses that deal with storing and moving goods.

Autonomous Robots

Autonomous Robots

AGV Robot

AMR Mobile Robot

Truck

Robot Arms

Robot Forklift

SMARTer Storage

(ASRS & Pallet Shuttle)

Smart Storage consists of a variety of computer-controlled systems for automatically storing and retrieving loads using stacker crane, pallet shuttle, lift, and small robots to/from defined storage locations. It is integrated with a warehouse control software (WCS), warehouse management software (WMS), or other software system.

Retrofit Pallet Shuttle to Fully Automate Loading & Unloading System

Retrofit Pallet Shuttle to Fully Automate Loading & Unloading System Full Automatization of the 2-ways pallet shuttle with Stacker Crane

Sophic Inventory Management System (SIMS)

Simplify the process and automating end-to-end production, business management, demand forecasting and accounting

SMARTer Logistic

Consist of Autonomous Materials Handling Vehicles: Forklift, Reach Truck, AMR, AGV, etc.

Products you may be interested in

Material Management System (MMS)

By streamlining material-related processes, optimizing inventory levels, and ensuring materials are available when needed, MMSs contribute to improved operational efficiency, cost control, and customer satisfaction.

Learn More

Gold Wire Management System (GWMS)

GWMS consists of a set of automated robots that are used to load and unload gold wire spools from storage, as well as to dispense gold wire to wire bonding machines. It can help to improve the efficiency and traceability of gold wire usage, as well as to reduce the risk of contamination.

Learn More

InnoLocker SMARTer

InnoLocker is a smart storaging device that allows user to lock and unlock a cavity by sending secure signals from internal server, a mobile or tablet.

Learn More

RFID IoT Solution

RFID IoT solutions offer a holistic view of operations and enable organizations to make data-driven decisions that optimize processes, reduce costs, and enhance overall efficiency.

Learn MoreADDRESS

Penang Main Office

9, 1, Jln Industri Tangkas, Taman Industri Tangkas,

14000 Bukit Mertajam Penang.

Penang Beta

6 & 8, Lorong Perindustrian Bukit Minyak 1/1,

Kawasan Perindustrian Bukit Minyak,

14100 Simpang Ampat, Pulau Pinang

Kuala Lumpur

21-13A & 21-16, Stellar Suites, Jalan Puteri 4/7,

Bandar Puteri, 47100 Puchong, Selangor.

Tel: (603) 8604 7311

SOPHIC AUTOMATION SDN BHD

(2007010136965(794994-D))

A pure play technology company, we have delivered proven automation solutions and engineering services to more than 50 MNCs & SMEs in South East Asia.

Email: enquiry@sophicautomation.com

©2023 Copyright Sophic Automation Sdn Bhd. All Rights Reserved | Terms of Use | Privacy | Site Map